Success Story:

Electric (construction) vehicles

INRO in electromobile (construction) vehicles

As the central component of every electric drivetrain, power electronics have important tasks in vehicles and work machines: effective and efficient control of the electric machine, communication with the vehicle control system and drive diagnostics.

INRO products are specially adapted to the needs of customers - whether for high handling capacities in the world's most modern industrial trucks and logistics centres or, as here, for demanding use in the most adverse environmental and weather conditions.

Electric vehicles must be equipped for demanding use in the most adverse environmental and weather conditions. It requires a technology that fulfils the customer's requirements and at the same time provides efficient and effective control in vehicles.

At the same time, the technology must be able to withstand various conditions such as heat, cold, sand, dust and moisture without losing performance or life expectancy.

- DMC - Dual Motion Control combination control

- TMC - Drive control Triple Motion Control

- Efficient systems:

Control units that can be used to control several motors simultaneously. - Versatile use:

Suitable for use with asynchronous, synchronous and synchronous reluctance motors. - Resistant:

Robust and sealed housing for extreme weather conditions - Various bus systems:

Implemented for communication such as CAN bus or MODBUS

INRO has been developing and manufacturing high-performance drive controls - made in Germany - for over 30 years and is continuously driving forward their technological development. The focus is on modern control technologies, energy efficiency and sustainable system solutions that enable continuous optimisation and adaptation to current market and environmental requirements.

Systems thinking is a central component of our development approach. In addition to pure drive control, additional application-specific requirements can be mapped using modular add-ons. As a manufacturer of electrical system components, we pursue a holistic approach in which we consider the entire vehicle or machine and systematically integrate our components.

Our drive controls for electrically powered machines are designed for use in a wide variety of (construction) vehicle types. Whether industrial trucks, off-highway work machines or construction machinery such as wheel loaders - all control systems are precisely designed and configured by our development team to meet the vehicle-specific requirements, the operating environment and applicable safety standards.

The project

in detail

Every project begins with intensive technical coordination with the customer. The aim is to precisely record all product-specific requirements and jointly define innovative functional enhancements. We also take on an advisory role in order to optimise the integration of our control solutions into existing vehicle architectures and increase system efficiency in a targeted manner.

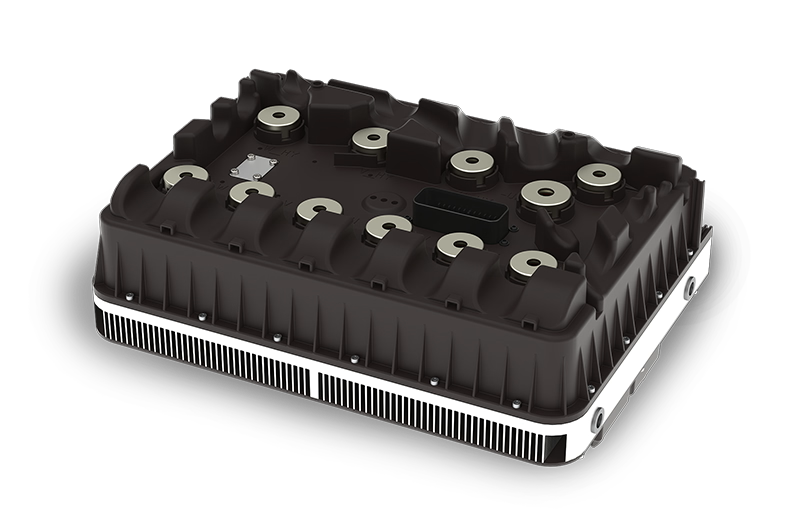

TMC (Triple Motion Control) and DMC (Dual Motion Control) are highly integrated, high-performance drive control systems for controlling asynchronous motors or synchronous reluctance motors. Both systems fit seamlessly into the overall architecture of a vehicle. The DMC is designed to control two axles, while the TMC - in keeping with its name - controls up to three axles. Output stages 1 and 2 of the TMC can also be connected in parallel to form an even more powerful output stage.

As a compact controller, the DMC performs several functions in a single control unit: it combines the vehicle control computer, the safety computer, I/O modules and the control unit for the traction drive and hydraulics in a single integrated unit. This system consolidation not only increases functionality, but also significantly reduces the required installation space - a decisive advantage in modern, space-critical vehicle applications.

The customer provided specifications that required the development of control units that could be integrated into confined installation spaces and at the same time fulfil high performance requirements. The control units are designed for use in mobile (off-highway) machinery in outdoor applications and must therefore offer reliable protection against the ingress of water and dirt.

The TMC is equipped with a robust, sealed housing in accordance with protection class IP69K (without fan). This protection class guarantees complete protection against dust and water, even with high-pressure and hot water cleaning. The suffix "K" explicitly indicates protection against high water temperatures. The DMC corresponds to protection class IP68 (also without fan).

Both control units also fulfil the requirements for functional safety in accordance with DIN EN ISO 13849. The DMC compact control unit is equipped with a safety computer that enables safety functions up to performance level d, category 3. The TMC has a two-channel emergency stop shutdown function that enables the three-phase AC drives to be safely stopped in accordance with Performance Level d Category 3 as per EN ISO 13849-1.

We maintained close and continuous communication with the customer throughout the entire product development process. Functional prototypes were provided during the development phase to enable early testing under real conditions. The prototypes were manufactured using 3D printing processes and precise CNC milling, among other things.

After a six-month development period, the first functional prototype was delivered to the customer for field tests. Series production started on schedule in accordance with the previously agreed timetable.

Even after delivery of the control unit, we remain in regular dialogue with the customer - both to provide rapid assistance with support issues and to jointly develop the product for future vehicle generations.

TMCs

The drive control unit Triple Motion Control safety (TMCs) is a 3-axis controller for asynchronous and synchronous reluctance motors consisting of three independently operating subsystems, each with its own output stage and controller.

The TMCs enables:

- Drive control for all types of mobile machinery with up to three drives, such as traction, steering and pump drives or two traction drives and a hydraulic unit

- Rated battery voltage 80 V

- Input voltage range 56 V..104 V

- Highly efficient 3-axis power output stages with recuperation function (energy recovery)

- Boost mode with 900 Aeff

- Various bus systems for communication such as CAN bus or MODBUS

DMCs

The compact control unit Dual Motion Control safety (DMCs) is a 2-axis controller for asynchronous and synchronous reluctance motors consisting of two independently operating subsystems, each with its own output stage and its own computer.

The DMCs enable:

- Drive control for all types of mobile machinery with two drives, such as: travel and pump drives or two travel drives

- Rated battery voltage 80 V

- Input voltage range 48 V..96 V

- Two-channel I/O interface with a variety of inputs and outputs

- Application range - 40 °C to + 85 °C

Conclusion

Reliability, durability and robustness are among the key requirements for modern drive controls. The control systems developed by INRO not only fulfil these core requirements, but also fit perfectly into the existing architecture of the construction machine in order to exploit the full potential of the controlled motors. Both safety and security factors are implemented without compromising the performance of the drive controls.